As an Amazon Associate, I earn from your qualifying purchases. When you click an affiliate link, we get a small commission at no cost to you.

Are you interested in learning about 3D printing but don’t know where to start? In this article, you will explore the world of 3D printing and gain a basic understanding of how it works. By the end, you’ll grasp the fundamental concepts and be ready to embark on your own 3D printing journey.

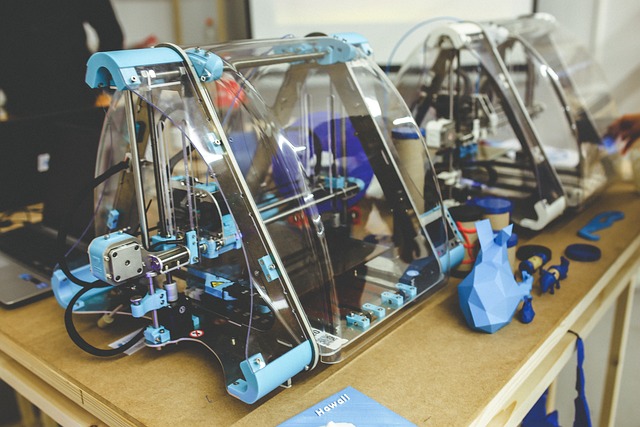

So, what exactly is 3D printing? Well, it’s a way to create physical objects from digital designs by layering materials one on top of another. As a beginner, you might be wondering what kind of 3D printer you should start with. Don’t worry, there are various options available that cater specifically to beginners. These printers are designed to be user-friendly and come with easy-to-use software. With a bit of practice, you’ll be able to bring your own 3D creations to life!

Introduction to 3D Printing for Beginners

Are you fascinated by the idea of turning digital designs into physical objects? Have you ever wanted to create your own customized products or prototypes? Look no further, because 3D printing is here to make your imagination come to life. In this article, we will explore what 3D printing is, how it works, the different types of 3D printers, the materials they use, and the steps involved in preparing, operating, and finishing a 3D print. By the end, you will have a better understanding of 3D printing and all the possibilities it offers.

What is 3D printing?

Definition of 3D printing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials on top of each other. Unlike traditional manufacturing methods that involve removing or shaping materials, 3D printing builds objects layer by layer from a digital design. It is a revolutionary technology that allows for rapid prototyping, customization, and on-demand production.

How 3D printing works

The process of 3D printing begins with a digital design created using 3D modeling software or downloaded from online repositories. The design is then sliced into thin layers, which are sent to the 3D printer. The printer, guided by the instructions in the sliced file, deposits or solidifies the selected material layer by layer until the complete object is formed. The material used can be plastic, metal, ceramic, or even biological in nature, depending on the printer’s capabilities and the desired application.

Advantages of 3D printing

3D printing offers numerous advantages over traditional manufacturing methods. Firstly, it allows for intricate and complex geometries that would be difficult or impossible to achieve with other techniques. This flexibility in design opens up endless possibilities for creativity and innovation. Secondly, 3D printing requires fewer raw materials, resulting in less waste and lower costs. It also enables on-demand production, eliminating the need for large inventories. Lastly, 3D printing democratizes manufacturing by making it accessible to individuals and small businesses, leveling the playing field in product development and production.

Types of 3D printers

Fused deposition modeling (FDM)

One of the most popular types of 3D printers is the Fused Deposition Modeling (FDM) printer. FDM works by melting a thermoplastic filament and extruding it through a nozzle. The nozzle moves in a controlled manner, depositing the molten plastic layer by layer to create the object. FDM printers are affordable and relatively easy to use, making them a popular choice for beginners and hobbyists.

Stereolithography (SLA)

Stereolithography (SLA) printers use a different approach to 3D printing. Instead of melting a filament, SLA printers use a liquid resin that is cured by a UV laser. The printer’s build platform is submerged in a vat of liquid resin, and the laser scans the surface, solidifying the resin layer by layer. SLA printers are capable of producing highly detailed and smooth prints, making them ideal for applications where precision is critical, such as jewelry or dental models.

Selective laser sintering (SLS)

Selective Laser Sintering (SLS) printers are commonly used for printing with metal or nylon powders. In SLS, a high-powered laser selectively sinters the powdered material, fusing it together to create the object. Unlike FDM or SLA printers, SLS printers do not require support structures, as the unsintered powder acts as the supporting material during the printing process. SLS printers are known for their strength and durability, making them suitable for industrial and engineering applications.

Materials used in 3D printing

Plastics

Plastics are the most commonly used materials in 3D printing due to their versatility and affordability. Different types of plastics, such as PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene), offer a range of properties, including strength, flexibility, and heat resistance. PLA is biodegradable and easy to print with, making it a popular choice for beginners. ABS, on the other hand, is known for its durability and is commonly used in functional prototypes or parts.

Metals

Metal 3D printing, also known as metal additive manufacturing, has gained significant attention in recent years. It involves melting metal powders or wire using a high-powered laser or electron beam to create fully dense metal parts. Metal 3D printing offers the ability to produce complex and intricate metal objects with properties comparable to traditionally manufactured metal parts. It has applications in aerospace, automotive, and medical industries, among others.

Ceramics

Ceramic 3D printing is a relatively new and evolving field. It involves depositing ceramic materials, such as alumina or zirconia, layer by layer to create ceramic objects. Ceramic prints can be fired at high temperatures to achieve the desired strength and quality. Ceramic 3D printing has applications in architecture, biomedical engineering, and the production of intricate ceramic artwork.

Preparing for 3D printing

Choosing a 3D design software

Before you can start 3D printing, you need to create or download a digital model of your desired object. For this purpose, you will need to choose a 3D design software. There are several options available, ranging from beginner-friendly software with intuitive interfaces to professional-grade software with advanced features. Some popular choices include Tinkercad, Fusion 360, and SolidWorks.

Creating or downloading a 3D model

Once you have selected a 3D design software, you can either create your own 3D models or download pre-made models from online repositories. If you choose to create your own models, the software will provide you with tools to design and manipulate geometric shapes. However, if you prefer not to start from scratch, you can explore online platforms like Thingiverse or MyMiniFactory, which offer a vast collection of downloadable 3D models created by the community.

Importing the 3D model to the slicing software

After finalizing your 3D model, you will need to import it into slicing software. Slicing software takes your 3D model and converts it into a format that the 3D printer can understand. It calculates the toolpath, or G-code, which instructs the printer on how to move, extrude or sinter the material, and build the object layer by layer. Slicing software also allows you to adjust various print settings, such as layer height, infill density, and print speed, to achieve the desired outcome.

Slicing and setting up the print

Slicing the 3D model into layers

When you import your 3D model into the slicing software, it automatically divides the object into multiple layers. Each layer represents a cross-section of the object that will be printed. The slicing software allows you to customize the layer thickness, also known as the layer height, which affects the level of detail and the overall print time. Thinner layers result in finer details but may increase the printing time.

Adjusting print settings

Before you generate the G-code, it is essential to adjust print settings according to your object’s specific requirements. These settings include the print speed, which determines how fast the printer moves, the temperature of the print bed and nozzle, and the fill density, which determines the percentage of the object’s interior that is solid. Fine-tuning these settings will ensure optimal print quality and reduce the likelihood of printing errors.

Generating the G-code

Once you have finalized your print settings, you can generate the G-code by clicking the appropriate button in the slicing software. The software processes your 3D model and converts it into a series of instructions that the printer can follow. The resulting G-code file contains information about layer heights, print speeds, toolpaths, and more. This file can be saved to an SD card or transferred directly to the 3D printer using a USB cable.

Operating a 3D printer

Loading and unloading filaments

To begin a 3D print, you need to load the filament into the printer. Filament is the material that will be extruded or sintered to create your object. Depending on the type of printer you have, this process may vary. For FDM printers, you will typically insert the filament spool into the printer and thread the filament through a filament guide tube and into the extruder. For SLA or SLS printers, you will pour or inject the liquid resin or powder into the printer’s reservoir.

Calibrating the print bed

Calibrating the print bed is a crucial step before starting a 3D print. The print bed needs to be leveled and at the correct distance from the nozzle to ensure proper adhesion of the first layer. Most 3D printers have built-in calibration routines that guide you through this process. By adjusting the bed’s three or four screws, you can ensure that the nozzle hovers at the ideal height above the print bed, providing optimal first-layer adhesion.

Starting and monitoring the print job

Once the filament is loaded, and the print bed is calibrated, you can start the print job. On the printer’s control panel or through the software interface, select the print file you want to run. The printer will begin heating the nozzle or bed to the required temperatures, and then start the printing process. Throughout the print, you should monitor the printer for any issues or errors, such as filament jams or layer adhesion problems. Proper monitoring ensures a successful print.

Post-processing and finishing

Removing support structures

After the 3D print is finished, it may require some post-processing, depending on the complexity of the model and the desired outcome. One common post-processing step is the removal of support structures. Support structures are temporary structures used to hold up overhanging or complex parts of the print during the printing process. They are typically printed with the same material as the object but are designed to be easily removable by hand, pliers, or cutting tools.

Sanding and smoothing the print

To achieve a smooth and polished finish on your 3D print, you may need to sand or smooth the surfaces. This step is particularly important for FDM prints, as they often have visible layer lines. Using sandpaper or abrasive tools, you can gently sand the surfaces, removing imperfections, and achieving a smoother texture. For more advanced finishing, you can apply epoxy resin or coatings to create a glossy or matte appearance.

Painting or applying finishes

If you want to add color and aesthetic appeal to your 3D print, painting or applying finishes is a great option. Acrylic paints or spray paints can be used to add vibrant colors or gradients to the object’s surface. Additionally, you can apply clear coatings, such as varnish or epoxy, to protect the print and give it a glossy, polished finish. This step allows you to personalize your prints and bring them to life with unique designs and patterns.

Troubleshooting common issues

Print quality problems

As a beginner, you may encounter various print quality issues while using a 3D printer. These can include uneven layers, stringing or oozing of filament, or warping of the print. Most print quality problems can be attributed to incorrect print settings, improper calibration, or design flaws. By fine-tuning your settings, calibrating the printer, and analyzing the print settings, you can identify and address these issues to improve your print quality.

Filament jams

Filament jams occur when the filament gets stuck in the nozzle or extruder, preventing the flow of material. This can happen due to a variety of reasons, such as a clogged nozzle, improper filament loading, or a misaligned extruder. To resolve filament jams, you can try cleaning the nozzle, inspecting and reseating the filament, or adjusting the extruder tension. Regular maintenance and cleaning can significantly reduce the occurrence of filament jams.

Printing errors

During the printing process, you may encounter errors that can interrupt or ruin your print. These errors can be caused by power interruptions, file corruption, or mechanical issues with the printer. To minimize the impact of printing errors, it is important to regularly save your progress and have backup power supplies. Additionally, maintaining your printer, lubricating moving parts, and ensuring proper alignment can help prevent mechanical errors.

Applications of 3D printing

Prototyping and product development

One of the major applications of 3D printing is rapid prototyping and product development. By 3D printing prototypes, designers and engineers can quickly iterate and test their designs before committing to mass production. This reduces the time and cost associated with traditional prototyping methods and enables faster product development cycles. 3D printing also allows for easy customization and personalization, making it ideal for creating unique products tailored to specific needs or preferences.

Medical and dental applications

3D printing has made significant advancements in the medical and dental fields. It is used to create patient-specific anatomical models for surgical planning and education. Surgeons can practice complex procedures on accurate replicas of patient organs, improving surgical outcomes and reducing the risk of complications. Additionally, 3D printing enables the production of customized medical implants, prosthetics, and orthotics, providing patients with better-fitting and more functional solutions.

Art and creative projects

The accessibility and versatility of 3D printing have sparked a new wave of creativity in the art world. Artists and designers are utilizing 3D printing to push the boundaries of traditional art forms and explore new artistic expressions. From intricate sculptures to functional fashion accessories, 3D printing offers a medium for artists to bring their visions to life. It allows for experimentation with complex geometries, material combinations, and interactive designs, fostering innovation and artistic diversity.

Conclusion

In conclusion, 3D printing is an exciting technology that opens up a world of possibilities for individuals and industries alike. With its ability to turn digital designs into physical objects, 3D printing has revolutionized manufacturing, prototyping, and product development. By understanding the basics of 3D printing, including the different types of printers and materials, the steps involved in preparing and operating a print, and the various applications of this technology, you can embark on your 3D printing journey with confidence. So go ahead, explore, experiment, and unleash your creativity with the fascinating world of 3D printing.