As an Amazon Associate, I earn from your qualifying purchases. When you click an affiliate link, we get a small commission at no cost to you.

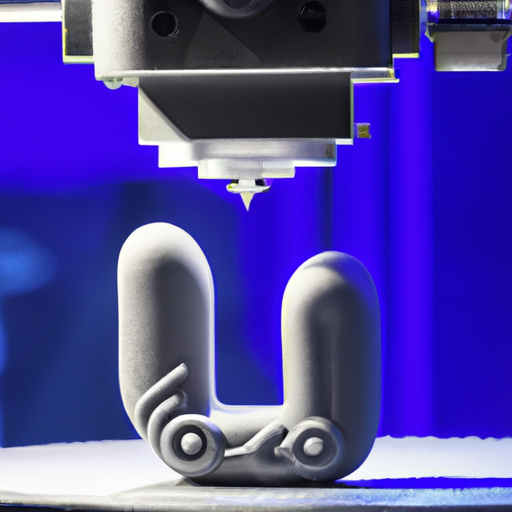

In this article, you will learn about the future of industrial 3D printing and the exciting possibilities it holds. We will discuss the advancements in technology and how it is changing the manufacturing industry. By the end, you will have a better understanding of the potential of industrial 3D printing and its impact on various sectors.

Industrial 3D printing is revolutionizing the way products are made. With the ability to create complex and customized designs, this technology is opening up a world of opportunities. From aerospace to healthcare, industries are finding innovative ways to utilize industrial 3D printers for production. In the future, we can expect even more advancements, such as faster printing speeds and improved materials, which will further enhance the capabilities of these printers. Get ready to dive into the exciting world of industrial 3D printing!

Overview of Industrial 3D Printing

Industrial 3D printing, also known as additive manufacturing, is a revolutionary technology that has completely transformed the manufacturing industry. This innovative process allows for the creation of three-dimensional objects by building them layer by layer using a variety of materials. Unlike traditional manufacturing methods, which require the removal of material through cutting or drilling, 3D printing adds material only where it is needed, resulting in increased efficiency and reduced waste.

Evolution of 3D Printing Technology

3D printing technology has come a long way since its inception in the 1980s. The first commercially available 3D printer was introduced in the late 1980s, but it was expensive and limited in its capabilities. However, advancements in technology and the development of new materials have led to significant improvements in 3D printing over the years.

One of the major advancements in 3D printing technology is the ability to print with a wide range of materials. Initially, 3D printers could only print with plastics, but now they can also print with metals, ceramics, and even biomaterials. This expanded material selection has opened up new possibilities for 3D printing in various industries.

Applications of Industrial 3D Printing

Industrial 3D printing has a wide range of applications across different industries. One of the major applications of 3D printing is rapid prototyping. 3D printing allows designers to quickly and cost-effectively create physical prototypes of their designs, enabling them to test and refine their ideas before moving into mass production. This saves both time and money, as it eliminates the need for expensive and time-consuming traditional prototyping methods.

Another major application of industrial 3D printing is in the production of customized products. Traditional manufacturing methods are often not cost-effective for producing small quantities of customized products, as they require expensive molds or tooling. With 3D printing, however, customization is as simple as adapting the digital design and printing a new product. This has led to an increase in personalized consumer goods, such as customized smartphone cases or jewelry.

Advantages and Limitations of Industrial 3D Printing

Industrial 3D printing offers numerous advantages over traditional manufacturing methods. One of the key advantages is the ability to produce complex geometries that would be impossible or expensive to manufacture using traditional methods. This allows for the creation of lightweight structures with intricate designs, such as in the aerospace industry, where weight reduction is critical.

Another advantage of 3D printing is the reduction of material waste. Traditional manufacturing methods often result in a significant amount of material being wasted during the production process. 3D printing, on the other hand, only uses the material that is required to build the object, minimizing waste and saving costs.

However, industrial 3D printing is not without its limitations. One of the main limitations is the speed of the printing process. While the technology has improved over the years, 3D printing is still slower than traditional manufacturing methods, making it less suitable for mass production. Additionally, the quality of 3D printed parts may not always meet the same standards as parts produced through traditional methods, requiring additional post-processing steps.

Current Trends in Industrial 3D Printing

Growth of the Industrial 3D Printing Market

The industrial 3D printing market has experienced significant growth in recent years and is expected to continue expanding in the future. According to a report by MarketsandMarkets, the global industrial 3D printing market is projected to reach $34.8 billion by 2024, with a CAGR of 23.5% from 2019 to 2024. This growth can be attributed to the increasing adoption of 3D printing across various industries, as well as advancements in technology and materials.

Emerging Materials in 3D Printing

With advancements in material science, new materials are constantly being developed for use in 3D printing. One notable example is the emergence of metal 3D printing. Metal 3D printing, also known as metal additive manufacturing, allows for the production of complex metal parts that are not feasible with traditional manufacturing methods. This technology has found applications in industries such as aerospace, automotive, and healthcare.

Another emerging material in 3D printing is biocompatible polymers. These materials can be used to create patient-specific implants and prosthetics in the medical sector. By tailoring the design to each individual patient, 3D printing allows for a precise fit and improves patient outcomes.

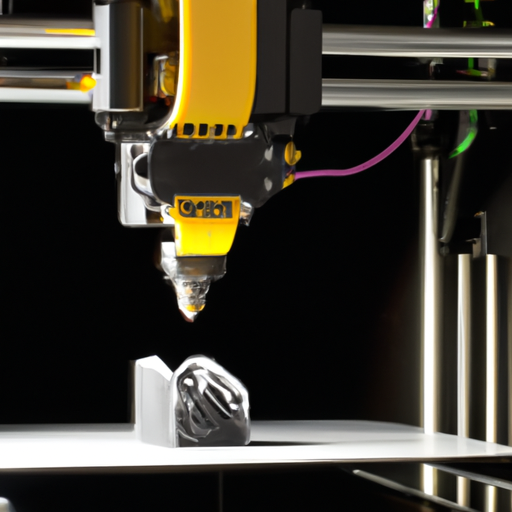

Automation and Robotics in Industrial 3D Printing

Automation and robotics are playing an increasingly important role in industrial 3D printing. Automated 3D printers can operate continuously without human intervention, allowing for increased production efficiency and reduced labor costs. Robots can also be used in post-processing steps, such as removing support structures or applying finishing touches to the printed parts.

Automation and robotics enable manufacturers to scale up their 3D printing capabilities and optimize their production processes. This has the potential to revolutionize the manufacturing industry, making it more efficient and cost-effective.

Impact of Industrial 3D Printing on Manufacturing

Customization and Mass Production

Industrial 3D printing has the unique ability to combine customization with mass production. Traditionally, the more customized a product is, the higher the cost of production. However, with 3D printing, customization comes at little to no additional cost, as the production process is based on digital design files. This opens up new opportunities for companies to offer personalized products to their customers without incurring significant additional expenses.

At the same time, 3D printing allows for efficient mass production by leveraging the benefits of additive manufacturing. By printing multiple products simultaneously and optimizing the layout of the build platform, manufacturers can achieve economies of scale and reduce production costs. This combination of customization and mass production has the potential to transform the manufacturing industry.

Supply Chain Optimization

3D printing has the potential to disrupt traditional supply chains by enabling localized production. With traditional manufacturing methods, products are often manufactured in one location and then shipped to different markets. This results in longer lead times, higher transportation costs, and increased carbon emissions.

With 3D printing, products can be manufactured on-demand and closer to the point of consumption. This eliminates the need for long-distance shipping and reduces the carbon footprint of the manufacturing process. Additionally, 3D printing allows for rapid iteration and design changes, reducing the need for costly inventory and minimizing the risk of obsolete stock.

Reduced Waste and Environmental Benefits

One of the key advantages of 3D printing is its ability to significantly reduce material waste. Traditional manufacturing methods often result in a significant amount of material being wasted during the production process, as excess material is removed through cutting, shaping, or drilling. In contrast, 3D printing only adds material where it is needed, minimizing waste and saving costs.

From an environmental perspective, 3D printing also offers several benefits. By reducing material waste, it helps conserve natural resources. In addition, 3D printing can enable the use of more sustainable materials, such as biodegradable polymers or recycled materials. This allows for the creation of products with a lower environmental impact, contributing to a more sustainable future.

Challenges and Future Developments

Quality Control and Certification

One of the challenges facing the widespread adoption of industrial 3D printing is ensuring consistent quality and meeting certification requirements. With traditional manufacturing methods, quality control processes are well-established and standardized. However, 3D printing introduces new complexities, such as variations in material properties and print quality.

To address this challenge, industry standards and certification processes for 3D printed parts are being developed. These standards will help establish guidelines for testing and validating the quality of 3D printed parts, ensuring their suitability for use in safety-critical applications, such as aerospace or medical devices.

Integration with Artificial Intelligence

As artificial intelligence (AI) continues to advance, there is great potential for its integration with industrial 3D printing. AI algorithms can optimize the design and manufacturing process, identify potential design flaws, predict material properties, and even suggest design improvements. This integration can lead to more efficient and cost-effective production, as well as improved product performance.

Furthermore, AI can be used to analyze large datasets generated during the 3D printing process, providing valuable insights for process optimization and quality control. By leveraging AI technologies, manufacturers can overcome existing challenges and unlock new possibilities in industrial 3D printing.

Metal 3D Printing and New Materials

Although metal 3D printing has already made significant advancements, there is still room for further development and improvement. Metal additive manufacturing is a complex process that requires precise control of variables such as laser power, scanning speed, and powder distribution. As technology continues to evolve, the speed and quality of metal 3D printing are expected to improve, making it more accessible and cost-effective.

In addition to metal 3D printing, new materials are constantly being developed for use in industrial 3D printing. For example, composite materials, which combine two or more materials with different properties, offer enhanced performance and functionality. By expanding the range of available materials, manufacturers can unlock new applications and drive further innovation in industrial 3D printing.

Revolutionizing the Aerospace Industry

Lightweight and Complex Structures

The aerospace industry has been at the forefront of adopting 3D printing technology. One of the major advantages of 3D printing in aerospace is the ability to create lightweight and complex structures. By optimizing the design and using advanced materials, such as aerospace-grade titanium alloys, 3D printed parts can be lighter and stronger than their traditionally manufactured counterparts. This leads to significant weight savings, which in turn translates to fuel efficiency and cost reduction in the aviation industry.

Rapid Prototyping for Design Iterations

Rapid prototyping is another area where 3D printing has revolutionized the aerospace industry. In the past, building physical prototypes of aircraft components and systems was a time-consuming and expensive process. With 3D printing, designers can quickly iterate their designs, test them, and make improvements in a matter of hours or days, rather than weeks or months.

This not only speeds up the design process but also allows for more innovative and optimized designs. Engineers can easily incorporate design changes based on test results, leading to improved performance and safety in aerospace applications.

On-Demand Spare Parts

The aerospace industry relies heavily on the availability of spare parts to ensure the smooth operation of aircraft. However, storing and managing a large inventory of spare parts can be costly and inefficient. 3D printing offers a solution to this problem by allowing for on-demand production of spare parts.

With 3D printing, aerospace companies can eliminate the need for large warehouses and expensive inventory, as parts can be printed as needed. This reduces lead times and costs associated with spare part procurement and storage, while ensuring the availability of critical components when needed.

Transforming the Medical Sector

Patient-Specific Implants and Prosthetics

Medical applications of 3D printing have transformed the healthcare industry, particularly in the area of implants and prosthetics. 3D printing enables the production of patient-specific implants and prosthetics, tailored to the individual’s anatomy. By creating custom designs based on medical imaging data, such as CT scans or MRIs, surgeons can ensure a precise fit and better patient outcomes.

Additionally, 3D printing allows for the integration of complex features, such as porous structures or internal channels, which can improve the performance and functionality of medical implants. For example, porous structures can promote bone ingrowth, enhancing the stability and longevity of orthopedic implants.

Bioprinting and Tissue Engineering

Another exciting development in the medical field is the emerging field of bioprinting. Bioprinting involves the printing of living cells and biomaterials to create functional tissues and organs. This has the potential to revolutionize the field of regenerative medicine and address the organ shortage crisis.

Bioprinting technology has already been used to create simple tissues, such as skin or cartilage, which can be used for transplantation or drug testing. However, the ultimate goal is to be able to create complex organs, such as hearts or kidneys, that can be transplanted into patients in need. While there are still many challenges to overcome, such as vascularization and cell viability, bioprinting holds great promise for the future of medicine.

Drug Delivery Systems

3D printing has also found applications in the field of drug delivery systems. Traditional pharmaceutical manufacturing involves mass producing medications in standard doses, which may not be suitable for all patients or conditions. With 3D printing, customized drug delivery systems can be created that meet the unique needs of each patient.

For example, 3D printed tablets can be designed to have different release profiles, allowing for precise dosing and individualized treatment. This personalized approach to drug delivery has the potential to improve patient adherence and therapeutic outcomes.

Innovations in Automotive Manufacturing

Prototyping for Concept Cars

The automotive industry has embraced 3D printing for rapid prototyping of concept cars. Designers and engineers can use 3D printing to create physical models of their designs, allowing them to evaluate aesthetics, fit, and functionality before moving into mass production. This enables faster design iterations and reduces the time and cost associated with traditional prototyping methods.

Additionally, 3D printing allows for the creation of complex geometries and intricate designs that would be difficult or expensive to produce using traditional manufacturing methods. This gives automotive designers the freedom to push the boundaries of design and create truly unique and innovative vehicles.

Customized Automotive Components

3D printing also offers opportunities for customization in the automotive industry. With traditional manufacturing methods, producing customized automotive components can be expensive and time-consuming, as it often requires specialized tooling or molds. 3D printing eliminates the need for these additional steps, making customization more accessible and cost-effective.

Customized automotive components can range from personalized interior features, such as dashboard trims or seat covers, to exterior parts, such as grille inserts or spoilers. This allows car owners to add a personal touch to their vehicles and create a truly one-of-a-kind driving experience.

Reduced Lead Times and Cost

Another benefit of 3D printing in automotive manufacturing is the reduced lead times and cost associated with producing certain parts. Traditional manufacturing methods often require significant lead times for tooling and setup, as well as high material and labor costs. With 3D printing, parts can be produced on-demand and without the need for expensive tooling, reducing both time and cost.

This is particularly valuable for low-volume production, where the cost of traditional manufacturing methods may not be justified. Instead of investing in tooling and setting up a production line, automotive manufacturers can simply 3D print the parts as needed. This flexibility and cost savings can be a game-changer for smaller automotive companies or niche markets.

Advancements in Construction and Architecture

Large-Scale 3D Printed Buildings

The construction industry is also starting to embrace 3D printing technology, with the potential to revolutionize the way buildings are designed and constructed. Large-scale 3D printers can fabricate entire building structures, layer by layer, using a variety of materials, such as concrete or composite materials.

One of the main advantages of 3D printing in construction is the ability to create complex and intricate designs that would be difficult or expensive to achieve using traditional construction methods. This allows for architectural freedom and design possibilities, enabling the creation of unique and aesthetically pleasing structures.

Furthermore, 3D printing in construction has the potential to significantly reduce construction time and labor costs. The automation provided by 3D printers allows for faster and more efficient construction processes, eliminating the need for manual labor-intensive tasks. This can lead to cost savings and increased productivity in the construction industry.

Sustainable Construction Practices

In addition to design flexibility and cost savings, 3D printing in construction also offers environmental benefits. By using additive manufacturing techniques, construction waste can be minimized, as 3D printing only adds material where it is needed. This reduces the amount of material waste generated during the construction process, contributing to a more sustainable construction industry.

Furthermore, 3D printing allows for the use of eco-friendly materials, such as recycled concrete or environmentally friendly polymers. These materials have a lower carbon footprint compared to traditional construction materials, making 3D printed buildings more sustainable and environmentally friendly.

Architectural Freedom and Design Possibilities

With 3D printing, architects and designers are no longer limited by conventional construction methods and materials. The ability to create intricate and complex designs opens up new possibilities for architects to push the boundaries of design and create innovative and unique structures.

One notable example is the MX3D Bridge in Amsterdam, which was created using 3D printed stainless steel. The bridge, with its intricate and organic design, showcases the possibilities of 3D printing in architecture.

By harnessing the power of 3D printing, architects can create designs that were previously unimaginable, allowing for more creativity and innovation in the architectural field.

3D Printing in Electronics and Consumer Goods

Miniaturized and Complex Electronic Components

The electronics industry has also been greatly impacted by 3D printing. Additive manufacturing allows for the creation of miniaturized and complex electronic components that are critical to the development of advanced electronics.

With traditional manufacturing methods, creating small and intricate electronic components can be very challenging and costly. 3D printing, however, offers a more precise and efficient way to produce these components. By printing layer by layer, 3D printers can create intricate circuitry and complex geometries that are essential for the miniaturization of electronics.

3D printing also enables the integration of multiple functions into a single component, reducing the need for assembly and improving the overall performance and reliability of electronic devices.

Personalized Consumer Products

The consumer goods industry has also embraced 3D printing as a means of personalization. With the ability to quickly and cost-effectively produce unique and customized products, 3D printing has opened up new possibilities for manufacturers to offer personalized consumer goods.

From customized jewelry and accessories to personalized smartphone cases or home decor items, 3D printing allows consumers to express their individuality and own one-of-a-kind products. This customization trend is seen as a way to enhance the consumer experience and increase customer satisfaction.

Rapid Manufacturing of Gadgets

Another application of 3D printing in the consumer goods industry is rapid manufacturing of gadgets. Gadgets such as drones, cameras, or headphones often require customized or specialized parts that may not be readily available or cost-effective to produce using traditional manufacturing methods.

With 3D printing, these parts can be quickly and easily produced on-demand, reducing lead times and costs associated with spare part procurement. This allows for faster repair and replacement of gadgets, improving the user experience and reducing downtime.

By leveraging the benefits of 3D printing, the consumer goods industry can offer more customized and innovative products and address the evolving needs and preferences of consumers.

Conclusion

Industrial 3D printing has revolutionized the manufacturing industry, offering a wide range of benefits and possibilities across various sectors. From rapid prototyping to mass customization and reduced waste, the impact of 3D printing on manufacturing is undeniable.

As the technology continues to evolve and new materials and techniques are developed, it is expected that the adoption of industrial 3D printing will continue to grow. The future of industrial 3D printing holds great promise, with advancements in quality control, integration with AI, and the development of new materials.

With its ability to create lightweight and complex structures, 3D printing is set to revolutionize industries such as aerospace, automotive, construction, and electronics. The medical sector will also benefit greatly from 3D printing, with applications ranging from patient-specific implants to bioprinting of functional tissues and organs.

The potential of industrial 3D printing is vast, and its impact on the manufacturing industry will continue to be transformative. With expectations for continued growth and innovation, 3D printing has the power to shape the future of manufacturing. So, embrace the future and get ready to 3D print your way to success!