As an Amazon Associate, I earn from your qualifying purchases. When you click an affiliate link, we get a small commission at no cost to you.

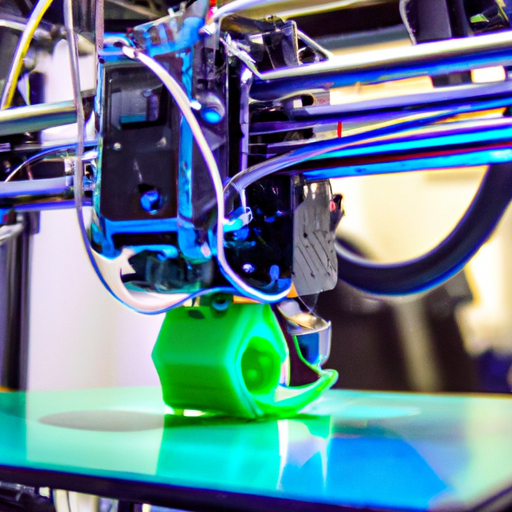

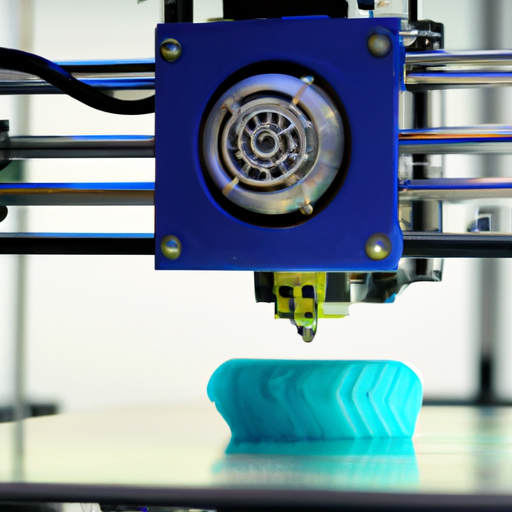

Hey there! Have you ever heard of the 3D printing revolution? Well, let me tell you, it’s going to change the future of manufacturing as we know it. With the rise of 3D printing technology, we’re entering a new era where we can create objects right from our fingertips. Imagine being able to print out any object you want, from toys to tools, all in the comfort of your own home. It’s truly mind-blowing!

Now, I know you must be curious to learn more about this incredible technology. In the upcoming article, we’ll dive deep into the world of 3D printing and explore how it’s already making an impact in various industries. We’ll look at the different types of 3D printers available, the materials they can use, and the endless possibilities they offer. Get ready to be amazed by the limitless potential of 3D printing and how it will shape the future of manufacturing. Stay tuned for more fascinating information coming your way!

Introduction to 3D Printing

What is 3D Printing?

3D printing, also known as additive manufacturing, is an innovative technology that allows you to create three-dimensional objects by layering materials one on top of another. It has the potential to revolutionize the way we manufacture products, offering endless possibilities in terms of design, functionality, and customization.

History of 3D Printing

The origins of 3D printing can be traced back to the 1980s when the first functioning 3D printer was developed by Charles Hull. This technology, known as stereolithography, used ultraviolet light to solidify liquid resin in successive layers. Since then, there have been numerous advancements and breakthroughs in the field of 3D printing.

Applications of 3D Printing

The applications of 3D printing are vast and diverse. From healthcare and aerospace to automotive and retail, this technology has found its place in various industries. It is used to create prototypes, custom-made products, replacement parts, architectural models, and even human tissues and organs. The possibilities are limited only by our imagination.

Advantages of 3D Printing

Cost Efficiency in Manufacturing

One of the greatest advantages of 3D printing is its cost efficiency in the manufacturing process. Traditional manufacturing methods often involve expensive tooling and molds, which can significantly increase the production costs. With 3D printing, these upfront costs are eliminated, and you can produce complex objects at a fraction of the traditional manufacturing cost.

Customization and Personalization

Another key advantage of 3D printing is its ability to produce highly customized and personalized products. Traditional manufacturing relies on mass production, where one design fits all. However, with 3D printing, you have the freedom to create unique designs tailored to individual needs and preferences. This customization leads to increased customer satisfaction and opens up new business opportunities.

Reduced Material Waste

3D printing also offers the advantage of reduced material waste. Unlike traditional manufacturing, where excess material is often discarded, 3D printing only uses the exact amount of material required to create the object. This not only reduces waste but also allows for more sustainable and eco-friendly production practices.

Impact of 3D Printing on Manufacturing

Disruption in Traditional Manufacturing Processes

The advent of 3D printing has brought about a disruption in traditional manufacturing processes. It challenges the conventional notion of mass production and shifts the focus towards decentralized manufacturing. With 3D printing, you can create products on-demand, eliminating the need for large-scale production facilities and warehouses.

Shift towards On-Demand Production

3D printing enables on-demand production, where products are created only when needed. This eliminates the need for stockpiling inventory, reducing costs associated with storage and supply chain management. On-demand production also allows for greater flexibility and responsiveness to market demands, leading to faster turnaround times and increased customer satisfaction.

Supply Chain Optimization

Another significant impact of 3D printing on manufacturing is the optimization of the supply chain. Traditional manufacturing often involves complex and lengthy supply chains, with multiple intermediaries and transportation logistics. With 3D printing, products can be created locally, eliminating the need for long-distance shipping and reducing carbon emissions. This localized production also reduces the risk of supply chain disruptions and increases resilience in times of crisis.

Technological Developments in 3D Printing

Introduction of Metal 3D Printing

One of the recent technological developments in 3D printing is the introduction of metal 3D printing. This advancement allows for the creation of complex metal parts with precision and accuracy. Metal 3D printing has opened up new possibilities in industries such as aerospace, automotive, and healthcare, where high-strength materials are required.

Advances in Bioprinting

Bioprinting, a subfield of 3D printing, focuses on creating living tissues and organs. Recent advancements in bioprinting have brought us closer to the possibility of printing functional organs for transplantation. This has the potential to revolutionize healthcare, saving countless lives and reducing the demand for organ donors.

Integration of 3D Printing with AI

The integration of 3D printing with artificial intelligence (AI) is another significant technological development. AI algorithms can optimize 3D designs, improve manufacturing processes, and analyze data for quality control. This integration enhances the efficiency and accuracy of 3D printing, making it even more suitable for large-scale production.

Challenges and Limitations of 3D Printing

Slow Production Speed

While 3D printing offers numerous advantages, it is still relatively slow compared to traditional manufacturing methods. The layer-by-layer printing process can take hours or even days to complete, depending on the complexity and size of the object. This limitation makes 3D printing less suitable for mass production and time-sensitive manufacturing needs.

Limited Material Options

Although the range of materials available for 3D printing has expanded over the years, it is still relatively limited compared to traditional manufacturing processes. Materials such as plastics and metals are commonly used in 3D printing, but options for specialized materials are still limited. This can pose challenges for industries requiring specific material properties for their products.

Quality Control and Regulatory Issues

Ensuring consistent quality and meeting regulatory standards can be challenging in 3D printing. The layer-by-layer construction process can result in imperfections and structural weaknesses, especially in complex designs. Additionally, there may be regulatory hurdles to overcome, particularly in industries such as healthcare, where strict standards are in place for safety and efficacy.

Implications for Various Industries

Automotive Industry

The automotive industry has been quick to adopt 3D printing technology for rapid prototyping, custom parts, and tooling. The ability to create complex geometries and lightweight structures has led to improved fuel efficiency and reduced production costs. 3D printing has also facilitated the development of electric vehicle components and autonomous vehicle technology.

Healthcare and Medical Devices

3D printing has the potential to revolutionize healthcare and the production of medical devices. Customized implants, prosthetics, and surgical tools can be created with precision and speed. Bioprinting is also paving the way for tissue engineering and regenerative medicine, with the possibility of printing functional human organs for transplantation.

Consumer Products and Fashion

3D printing has opened up new possibilities in consumer products and fashion industries. Customized jewelry, footwear, and accessories can be created, catering to individual preferences and styles. It also allows for rapid prototyping and iterative design processes, reducing time to market for new products.

Future Trends in 3D Printing

Scaling up 3D Printing

One of the future trends in 3D printing is scaling up the technology for large-scale production. As the speed and efficiency of 3D printers improve, it becomes feasible to produce larger objects, such as furniture and building components. This opens up new opportunities for the construction industry and reduces the carbon footprint associated with traditional building methods.

Integration of 3D Printing in Everyday Life

As 3D printing becomes more accessible and user-friendly, it is expected to integrate seamlessly into everyday life. Consumer-grade 3D printers may become a common household appliance, allowing individuals to create customized products on-demand. This shift towards decentralized manufacturing has the potential to transform the way we consume goods and reduce our dependence on global supply chains.

Emerging Applications in Aerospace and Defense

The aerospace and defense industries are also embracing 3D printing technology for its benefits in lightweight design and rapid prototyping. The ability to create intricate and highly complex geometries allows for the production of lighter and more fuel-efficient aircraft components. Additionally, 3D printing enables the rapid production of spare parts and reduces the logistical challenges associated with maintaining military equipment in remote locations.

Sustainability and Environmental Impact

Reduction in Carbon Footprint

One of the significant environmental benefits of 3D printing is the reduction in carbon footprint. With localized production and on-demand manufacturing, there is a decrease in transportation and storage-related emissions. Additionally, the reduced material waste and efficient use of resources contribute to a more sustainable manufacturing process.

Recycling and Circular Economy

3D printing offers opportunities for recycling and the promotion of a circular economy. Leftover or failed prints can be recycled and reused, reducing overall material waste. Furthermore, the ability to repair and modify existing objects using 3D printing extends the lifespan of products, reducing the need for new manufacturing.

Localized Manufacturing

The concept of localized manufacturing, made possible by 3D printing technology, has significant implications for sustainability. By producing goods closer to the point of consumption, the need for long-distance shipping is reduced, resulting in lower greenhouse gas emissions. Localized manufacturing also fosters the growth of local economies and reduces dependence on foreign imports.

Social and Economic Implications

Job Displacement and Skill Shift

The widespread adoption of 3D printing may lead to job displacement in traditional manufacturing industries. As automated printing processes replace manual labor, there is a need for workers to acquire new skills in operating and maintaining 3D printing technologies. Upskilling and retraining programs will be crucial in ensuring a smooth transition for the workforce.

Economic Opportunities and Entrepreneurship

On the other hand, the 3D printing revolution also brings economic opportunities and entrepreneurship. The accessibility of 3D printing allows individuals to start their own businesses and bring their ideas to life. It levels the playing field and reduces barriers to entry, empowering small-scale manufacturers and innovators.

Accessible and Affordable Customization

The democratization of customization is another social implication of 3D printing. Individuals no longer have to rely on mass-produced products but can create personalized items that suit their unique needs and preferences. This shift towards accessible and affordable customization promotes individuality and self-expression.

Join the 3D Printing Revolution

The future of manufacturing is bound to be transformed by the 3D printing revolution. With its cost efficiency, customization capabilities, and reduced environmental impact, 3D printing holds the potential to revolutionize industries and empower individuals. As technology continues to advance and overcome its current limitations, we can expect to see 3D printing further integrated into our everyday lives, offering new opportunities and challenging traditional manufacturing processes. The journey has just begun, and the possibilities are limitless. Embrace the 3D printing revolution and unlock a world of endless innovation and creativity.